Welcome

CI Precision continues to lead the way in the development of precision instruments and systems for use in quality assurance and research. Our foundation in 1965 was to manufacture the world’s first precision electronic microbalances for research applications. Today our expertise includes high precision weighing & handling, software solutions design, electronic design and the provision of GMP solutions for manufacturing.

Our precision weighing technologies and digital transformation platform transform quality control processes in regulated industries by combining exceptional accuracy, elegant design and compliance-ready solutions. Our customers include the world’s top pharmaceutical and bio-tech, industrial, agritech and aerospace companies, universities and other organisations.

The Detail

Company Profile

Investment in innovation

Throughout our 50 year history we have prioritised the continual investment in innovation, focussed on helping our customers achieve their ambitions with intelligent technology solutions. A family-run company, we start with a very good understanding of your key business drivers, the challenges you face and the specific applications where our technology adds value.

Proprietary technology

At CI Precision, the entire value chain from basic research to planning, design, and manufacture to sales and service is all under one roof.

Deliberately maintaining short communication channels, provides the guarantee of maximum flexibility in the implementation of every individual product configuration.

Uncompromising quality

We deliver exceptionally high levels of customer satisfaction; almost everyone who has ever bought one of our products is still actively using it. From the outset, part of our driving vision has been about consistent, dependable accuracy married with longevity and ROI for our customers. We have an excellent track record for on-time, on-budget delivery. Right first time.

Elegant design & intelligent solutions

Every piece of CI Precision technology is a response to a customer requirement.

Our long term commitment to innovation investment enables us to provide the most intuitively designed technology, with systems integration and validation prioritised throughout the entire product lifecycle.

Relationships underpin everything we do

We have a proven history of building long-term, worldwide relationships that provide continual value to our customers and partners.

We have an open, partner-based approach to delivering projects, working with you to meet your project goals; big company benefits whilst maintaining the family-run personal approach.

International installed base

25 of the world’s top 30 pharmaceutical companies use CI Precision technology.

Our customers have access to local customer service, anywhere in the world, thanks to our partner network with a presence on 5 different continents.

Find a vendor

Our Work

Case Studies

Read how we are helping businesses like yours meet their challenges.

Automated, high-precision weight sorting for superior quality control

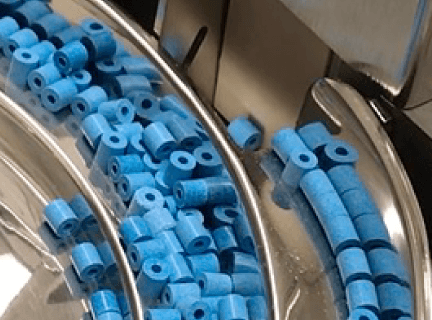

When Harwell Dosimeters wanted to control the manufacturing quality of their Alanine Pellets they chose CI Precision’s weight sorters to accurately weigh each pellet.

MoreGain total quality assurance in industrial parts manufacturing

SPIROL UK wanted to verify that their Coiled Spring Pins were manufactured to a consistently high weight quality to ensure robust quality assurance in their processes.

MoreMaintaining excellent accuracy and stability in experiments

Delft Solids Solutions needed a highly sensitive analytical instrument that can be used in research experiments for precise measurements of very small amounts of material.

MoreOur Story

Company History

Some of the business and product development milestones that we are justifiably proud of.

2020s

2020s Launch of SP X60 Range providing enhanced compliance and audit trail capabilities

2023 SP X60 Range

The SP X60 Range is launched. The same tried and tested SADE SP mechanical build now features enhanced firmware enabling features such as full 21 CFR Part 11 and Annex 11 compliance and full audit trail capabilities. Domain authentication and OPC/UA data protocol are both made available.

2020 Weight Sorting Product Development

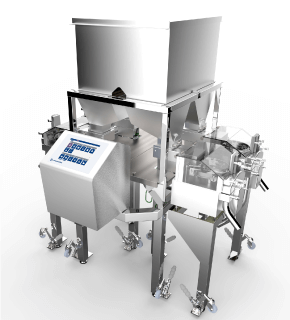

Introducing a five-way precision weight grading system to weigh, grade and sort every small part up to 8 grams to improve in-process sampling and quality control. The MX precision weight grader is the first of a new generation of products from CI Precision. It builds on the strengths of the SADE SP pharmaceutical range – accuracy, reliability and speed – with additional capabilities to meet the demands of industrial and food manufacturing. As a standard product it is ready to meet your needs out of the box.

2010s

Touch screen interfaces, SP link mode, 5 ways precision grader, MES developments and key business milestones; 50 years in business and 300th SADE SP weight sorter sold.

2018 Weight Sorting Business Milestones

SADE SP sales continue to soar with further expansion into the Far East with the first SADE SP240 weight sorter order for one of the leading Korean pharmaceutical manufacturers.

SADE tablet & capsule weight sorter sales increase with expansion into the nutraceutical market.

2016 Weight Sorting Business Milestones

May 2016 marked the three hundred sale of the SADE SP tablet & capsule weight sorter. Leading contract research company Aptuit purchased 3 SADE SP240s for its facility in Verona.

With the addition of a mini hopper the SADE SP-B40 Benchtop sorter can be left unattended, thereby minimising operator involvement. Designed for the 100% weight sorting of small development or clinical trial batches, this compact unit is ideal for the laboratory environment.

2015 Manufacturing Execution Systems Product Development

Release of version 6 of Ci-DMS is announced. With installations across four continents, the original weigh & dispense functionality has evolved on a modular basis to offer Manufacturing Execution System (MES) solutions for pharmaceutical manufacturing and packaging.

2015 marked 50 years in business for CI Precision. The company was originally formed to manufacture one of the world’s first precision electronic microforce balances for research applications. Five decades later, CI Precision is a thriving business with headquarters in Salisbury UK and distributors worldwide.

2013 Weight Sorting Business Milestones

SADE weight sorter sales increase with expansion into the veterinary market.

2010 Weight Sorting Product Development

A touchscreen interface is launched for all new SADE SP weight sorters. The touchscreen interface guides users through machine setup options and simplifies the process of running sort batches, while the new real-time display of batch data makes it easier to monitor the progress of each batch.

The launch of the SP Link mode allows the SADE weight sorters to be connected together to increase throughput whilst providing one consolidated record of the batch results. For a pharmaceutical manufacturing department, such increased performance mean a significant saving in time and costs when reclaiming acceptable product from a batch that has been rejected on a weight sampling test or for 100% weight checks.

2000s

First commercial off-the-shelf MES solution and SADE SP range of weight sorters launched.

2006 Weight Sorting Product Development

The SADE SP range of tablet and capsule weight sorters is launched with improved performance, increased functionality and a better overall user experience with industry compliance being a cornerstone of the design.

From formulation development through to clinical trials, from pilot-scale through to production, SADE SP is the only range that can meet all the industry’s weight sorting needs.

2002 Manufacturing Execution Systems Product Development

In 2002 we launched our first Commercial off-the-shelf (COTS) MES solution – Ci-DMS. Since the initial launch a number of releases have been published with increased functionality, flexibility and configurability to support all stages of manufacture from batch creation through to batch completion.

1990s

Tailor-made MES development and SADE P4 launch

1999 Weight Sorting Product Development

In 1999 the SADE P4 tablet and capsule weight sorter twin unit was launched. This provided twice the output and proved popular for larger batches.

1990s Manufacturing Execution Systems Business Milestones

Until the late 1990s we developed tailor made Manufacturing Execution System (MES) solutions for pharmaceutical customers across the UK and Europe including The Welcome Foundation, Eli Lilly, Glaxo, Smith Kline and French, ICI, Beechams, Roche Products, May and Baker, Orion, Sanofi, Squibb, Fisons and Merck Sharp & Dohme.

1970s

& 80s

Weight sorting product development including launch of SADE P2.

1980s Weight Sorting Product Development

During the 1970’s and 1980’s CI Precision (known as CI Electronics and CI Systems) designed and supplied average weight controllers for in process control and the first of our automatic balances for weighing tablets and capsules that used CI’s own weigh heads.

In 1986 the SADE P2 tablet and capsule weight sorter was launched. It soon gained a reputation with pharmaceutical manufacturers for quality and performance. Over 270 units were sold worldwide and many are still in service today.

1970s Manufacturing Execution Systems Product Development

CI Precision has been developing Manufacturing Execution System (MES) modules for the pharmaceutical industry since the early 1970’s. The first modules were statistical process control (SPC) and dispensary management systems (DMS).

1960s

Microbalance product development followed by first Manufacturing Execution Systems and SADE sorter.

1968 – Weight Sorting Product Development

The weight sorting of high value small sized items has been at the heart of CI’s activities since 1968. The SADE Sorter was first developed for the diamond industry.

1965 – Manufacturing Execution Systems Business Milestones

At that time, we developed software on mini computers such as the DEC PDP-11 and Data General rack mounted systems using VDUs and teletype terminals as I/O. We used a range of software languages but principally machine code, Fortran and Basic. Initial applications controlled our weighing and sorting systems. We sold these systems firstly to the diamond industry then more recently to the food and pharmaceutical industries.

1960s – Microbalances Product Development

In this innovative design, a “closed loop servo system” was established using an optical detector attached to the beam which via an amplifier continually adjusted the current level in the coil causing it to maintain the beam in its equilibrium position. Changes in the current were accurately proportional to the weight of the suspended sample. Digital displays were becoming available at the end of that decade so that the weight could be displayed continuously and it could be recorded and printed out repetitively in synchronism with time and any of the other parameters being monitored.

It comprised a miniature beam from one end of which the sample was suspended. Deflection of the beam was counteracted by a current in a coil attached to it which was positioned in the field of a permanent magnet. This used the Faraday effect, (dating from 1831), whereby the current in the coil is directly proportional to the torque applied to the beam. To operate the early microbalances, which used this principle, it was necessary to adjust a calibrated potentiometer to provide a current which set the beam to a null position.

Our Resources

Knowledge Hub

The latest updates and insights from our project team.

Connect with Us

Contact the CI Precision team today and book your individual project discovery session.