Back to news

Back to news

10 Features to Consider Before Buying a Checkweigher System

There are many benefits of using weight sorters in your operations. But whether new or used, not all weight sorters are made equal. There are many factors to consider to ensure you get the right checkweigher system for you. To help you make an informed decision when comparing checkweighers from different suppliers, check out our guide below.

1. Single or Multiple Product Batches?

Single product batches – look for outstanding reliability and accuracy.

Multiple product batches – look for versatility to handle any shape or size of product.

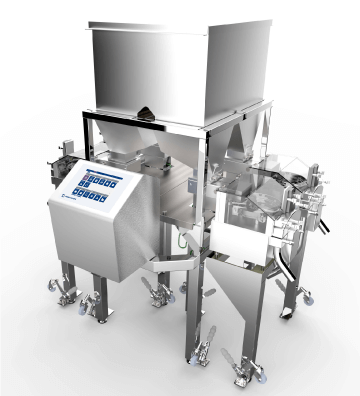

The SADE SP range of weight sorters has been designed to handle all shapes and sizes of products from tablets, capsules and soft gels to mini-tablets and implant dosage forms, with market-leading high-performance accuracy.

2. Minimise Downtime

Production Downtime – look for the ability to effect fast and efficient product changeovers – does the checkweigher require additional change parts?

Maintenance Downtime – does the whole machine need to be sent back for repair if only one weigh channel is not working?

With the SADE SP range of weight sorters, there is no need for costly format parts and time-consuming changeovers. Moreover, our multi-channel sorters can carry on operating even if one weigh unit is not working.

3. Your Quality Control Process

Is statistical batch sampling or 100% weight inspection assurance important?

Throughout the global healthcare sector, SADE SP weight sorters are a favoured choice. From the largest multinationals to the smaller organisations, our checkweigher systems are being used for statistical batch sampling, validating clinical trials and 100% weight sorting applications.

4. Process Improvements

Look for checkweighers that can provide statistical data for process improvements.

With the SADE SP range of weight sorters, statistical data access has been designed from the outset. From automated data capture and timestamping to tamperproof recordkeeping, it ensures that your quality control data is available for process improvements.

5. Mobility

Is the checkweigher mobile and compact to be placed where it is needed most?

Our SADE SP weight sorters have been designed specifically for healthcare research and manufacturing. They work equally well in any environment where you prepare or produce products, without any special preparation or modifications.

They are designed to be deployed in different locations and are fully mobile. In a production environment, they fit wherever you have space. Once positioned, they are perfectly stable on any level floor.

6. Hygienic Design

Look for a high standard of surface finish to improve your cleaning process and ensure your downtime is minimised.

The SADE SP range has been designed to ensure superior levels of GMP compliance and hygiene. All 316L and PEEK contact parts are guaranteed to a 0.8 Ra surface finish.

If a higher standard of surface finish is required, we offer a 0.5 Ra finish with certification.

7. Aseptic Conditions

Can the checkweigher work with containment solutions and can all contact parts be removed for cleaning without using tools?

SADE SP weight sorters are widely used in aseptic areas and we regularly work with customers to create custom containment solutions. Our standard units can operate reliably without maintenance between scheduled shutdowns and all contact parts can be removed for cleaning without using tools.

8. Working in Harsh Environment

Look for checkweighers that can operate in low humidity where static build-up is present and are robust to cope with vibrations or mechanical shock.

We can provide adapted weight sorters for use in extreme environments, such as in areas of low humidity, or if you have products that require extra special handling.

9. Operator Involvement

Can the checkweigher system be left unattended for long periods of time, freeing up your operators for other tasks?

No matter how large or small your batch, a SADE SP weight sorter provides 100% weight sorting, running reliably 24/7, without a technician in attendance. Every weighing is recorded and saved in a tamper-proof electronic record.

10. Reliability

To maximise your return on investment, reliability is key. Can you still rely on your equipment after years of use?

For over 50 years, CI Precision has remained the global leader in weight sorting and check weighing for healthcare. Our weight sorters are trusted to work reliably in any research or manufacturing environment. They have a very low cost of ownership and provide many years of service.

Which Checkweigher System is Right For You?

Your checkweigher system forms a critical part of your manufacturing and quality assurance processes, so it is important to choose the right solution for you and your business. There are different check-weighing solutions available on the market, each with features and benefits that suit different products, workplace setups and operating philosophies. A checkweigher with the right features can even help you overcome the industry challenges you might face in your day-to-day operations. Some things to think about when choosing your checkweigher system include:

- Fixed line or Multiple Products – short runs and batch sizes

- Minimise Downtime – fast and efficient product changeovers

- Your Quality Control Process – sampling or 100% quality assurance

- Process Improvements – statistical data to drive improvements

- Mobility – placed where it is needed most

- Hygienic Design – surface finish standard

- Aseptic Conditions – working with containment solutions

- Working In Harsh Environment – operating in low humidity

- Operator Involvement – left unattended for periods of time

- Reliability – still working after years of use

There are many aspects of check weighing to consider to ensure you get the right equipment for your products and business. We hope this list has given you some key pointers to think about when selecting your checkweigher. If you would like to learn more about our precision weighing solutions or discuss a project, please reach out to our team.