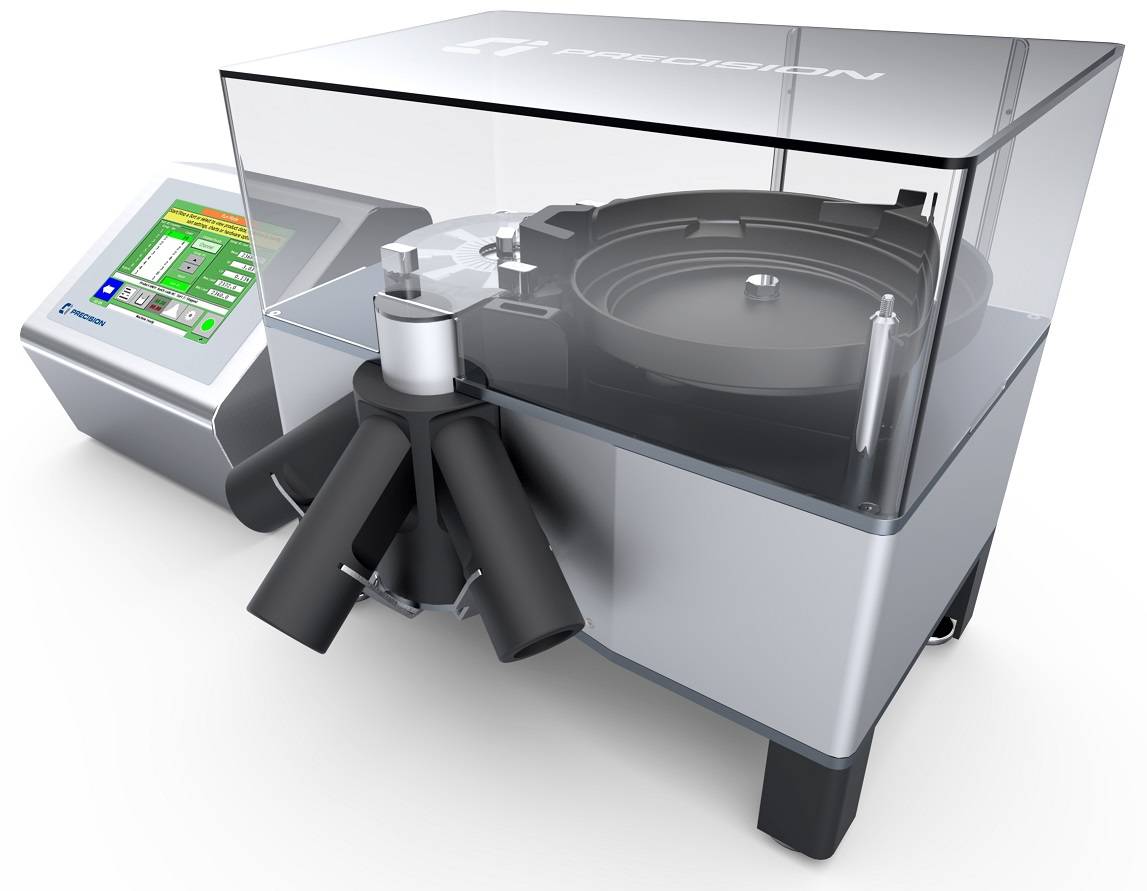

MX Precision weight grader – weigh, grade and sort quickly and accurately

5-Way Weight Grading for aerospace, research engineering, precision manufacturing and agritech

The MX Precision weight grader gives an accurate, fast and reliable way to weigh, grade to a specification, then sort by grade into batches for industries that require detection of small variations in weight at high speed.

Increase quality control, improve processes – reduce waste, ensure production quality, quickly detect defects, utilise data to enable automation and Industry 4.0.

If you have a quality control challenge and are seeking an effective solution, or wish to find out how MX can drive process improvement, contact us today at sales@ciprecision.com.

Precision weight grading for aerospace & research engineering

The MX’s unique ability to detect very small variations in weight at high speed is an efficient and cost-effective way of performing quality control in aerospace and research engineering. Research engineers rely on the MX to help drive process improvements to optimise the manufacturing process with increased efficiency, less material wastage, and improved yield.

Quality Control

- 100% inspection regimes

- Improve the design of component materials

- Ensure the structural integrity and reliability of components

- Enhance the manufacturing process with increased efficiency, less material wastage and improved yield

Process Improvement

- Catching issues early

- Identifying and eliminating root causes

- Assessing the impact of changes

- Adapting for variability in inputs

- Achieving tighter tolerances

Precision weight grading for precision manufacturing – including aluminium slugs

The weight of a slug can be a measure to determine alloy composition, production quality, process improvements, and much more, that could not be picked up with other inspection methods. Either stamped or sawn, the MX’s unique ability to detect very small variations in a slug’s weight at high speed, is an efficient and cost-effective way of performing quality control.

Quality Control

- 100% inspection regimes

- In-process sampling

- Batch recovery

- Process Improvement

Catching issues early

- Identifying and eliminating root causes

- Assessing the impact of changes

- Adapting for variability in inputs

- Achieving tighter tolerances

Precision weight grading for Agritech

The weight of an item can be a measure to determine potential yield, batch quality, and much more, that could not be picked up with other inspection methods. The MX’s unique ability to detect very small variations in weight at high speed is an efficient and cost-effective way of performing quality control in research.

Quality Control

- 100% inspection regimes

- In-process sampling

- Batch recovery

- Process Improvement

Catching issues early

- Identifying and eliminating root causes

- Assessing the impact of changes

- Adapting for variability in inputs

- Achieving tighter tolerances

Explore More

Continue Your Research

Find your local CI Precision partner

We work with partners around the world to provide expert local sales and support services. Contact us to find your local representative.

MoreSolve modern industry challenges with CI Precision

From our industry-leading precision weight sorters to advanced MES solutions, our products and services have been engineered to help you address and overcome your unique industry challenges.

MoreGain total quality assurance in industrial parts manufacturing

SPIROL UK wanted to verify that their Coiled Spring Pins were manufactured to a consistently high weight quality to ensure robust quality assurance in their processes.

Contact UsHow you can meet us

Request a meeting, or find us at an exhibition

Request a meetingUpcoming exhibitions