Why MES

Manufacturing execution systems (MES) have the potential to transform healthcare businesses, from the productivity of staff to consistency of production and integrity of recordkeeping. However, across healthcare and other sectors, there are as many stories of MES project failures as there are true commercial successes. So how should you approach MES to minimise risk and achieve the greatest return on investment?

Focusing on better processes

Based on many years of successful project delivery across the healthcare industry, we have seen that the true value of MES comes from changing and optimising your processes in ways that play to your business strengths. A successful MES project starts by looking at the process improvements that you want to make, and then defining your specific requirements. This will allow you to shortlist and evaluate MES systems on your terms, rather than being led by the limitations of one particular vendor.

Improving efficiency

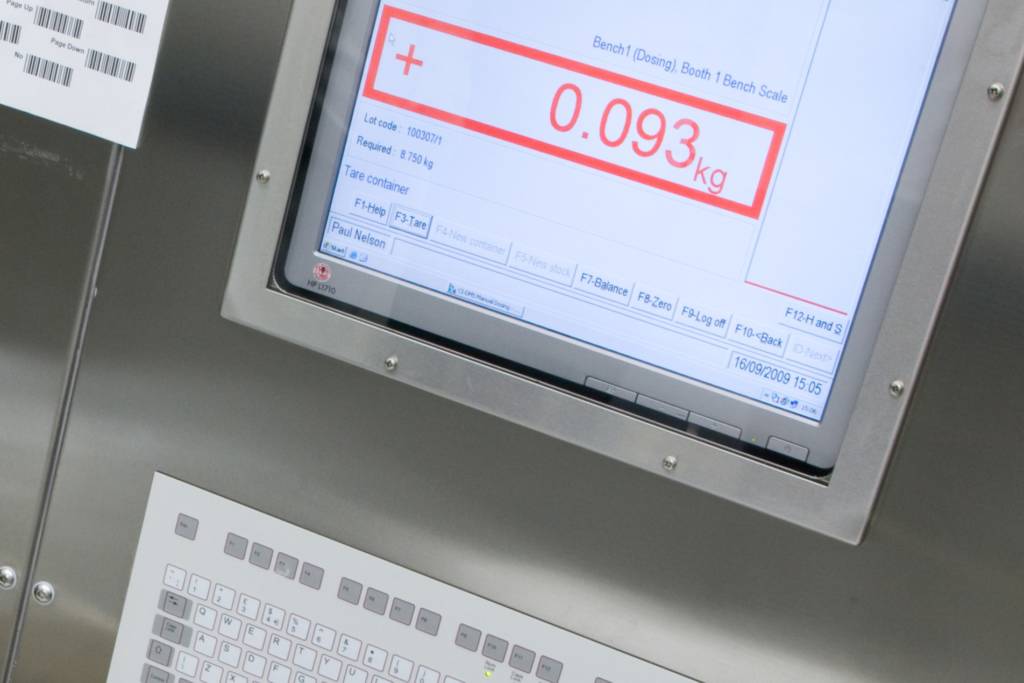

MES can help reduce labour through efficiency gains and the elimination of certain activities. By cutting the time that operators spend checking details, writing labels and completing paperwork, you need fewer people and/or fewer shifts. For example, where activities are tightly controlled by the system and the BRM is updated automatically, there is no need for second checkers. A lot of time-consuming data entry can also be eliminated, for example, stock consumption information is fed directly to your ERP system.

Boosting collaboration and communication

An MES provides a common platform for sharing real-time data and analytics. This enables departments to make informed decisions based on accurate and up-to-date information, reducing the risk of miscommunication since all stakeholders have access to the same data. Apart from streamlining production processes, an MES can help departments work together to identify, track and manage quality issues right from root cause analysis through to corrective action implementation.

By eliminating conflicting data and providing a centralised platform for managing production processes, different departments can communicate and collaborate more effectively, sharing resources, optimising workflows to improve efficiency and reducing waste.

Eliminating the cost of errors

Every healthcare manufacturer is committed to minimising human errors, but when they do inevitably occur, the associated costs can be very high. With Ci-DMS, errors are identified when they occur and the process is stopped before costs start escalating. Equally, when Quality identify an error or deviation, the ensuing investigation is often time-consuming and therefore costly. With an MES, you greatly reduce the number of errors but also have electronic records that quickly identify the causes.

Reducing wasted materials

One of the key areas in which MES delivers a return on investment is reducing waste. Across different healthcare clients, we have observed large differences, but in many cases, Ci-DMS has achieved substantial savings in waste ingredients. Even with moderately priced active ingredients, this can translate into a large financial benefit.

Ensuring regulatory compliance

By providing a single source of real-time data on manufacturing processes, MES systems help validate that quality assurance policies have been observed and enable manufacturers to gain greater visibility and control over their operations. With a centralised and auditable system for managing electronic records and signatures, MES systems can help reduce the risk of errors and improve data integrity. This is especially critical in the highly regulated pharmaceutical industry, where compliance with GMP requirements, anti-counterfeiting regulations and FDA mandates is a must.

Considerations for an implementation project

Software projects are notoriously difficult to manage. Some common reasons why these projects fail include a lack of top management commitment to the project, failure to gain user commitment, misunderstanding of process requirements, lack of adequate user involvement and failure to manage end-user expectations.

To ensure project success, it is essential to identify and manage risks. This involves identifying specific risk factors, ranking and rating them in terms of importance, and developing meaningful risk management strategies to counter these threats to success. In addition, it is also important for managers to establish clear communication with stakeholders to ensure that requirements are well understood and met throughout the project lifecycle.

In an industry where poorly executed projects can have disastrous consequences, it is important to partner with technology suppliers that have a proven track record of success. We are experts at implementing MES projects successfully here at CI Precision. Using our proprietary project management approach, we have extensive experience in helping our Pharma clients achieve first-time-right, on-time and budget MES implementation.

Specific figures

To enable your organisation to make an informed decision about MES and to prioritise it against other investments, we have developed a methodology and structure for creating a detailed business case. This cost-benefit analysis is based on a model of healthcare manufacturing but uses your processes and costs to provide realistic figures for return on investment.

White Paper - Benefits of a computerised dispensary

Download our white paper to find out how an MES enables first-time-right production in the manufacture of pharmaceutical products.

Explore More

Continue Your Research

Download the Ci-DMS MES brochure

Learn more about our Ci-DMS MES — our powerful, versatile, and modular software for paperless manufacturing that helps you tackle even the most exacting and demanding production requirements.

Download5 Factors to Consider When Choosing Your MES Partner

Selecting the right partner is as important as choosing the right MES solution. We understand..

Contact UsAutomated, high-precision weight sorting for superior quality control

When Harwell Dosimeters wanted to control the manufacturing quality of their Alanine Pellets they chose CI Precision’s weight sorters to accurately weigh each pellet.

Contact UsHow you can meet us

Request a meeting, or find us at an exhibition

Request a meetingUpcoming exhibitions